MAI CV

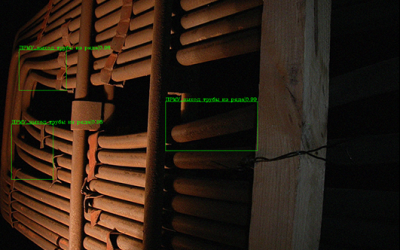

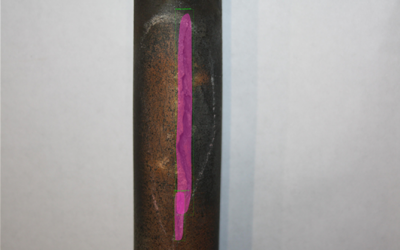

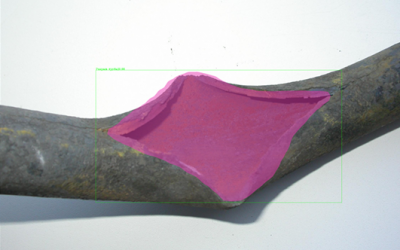

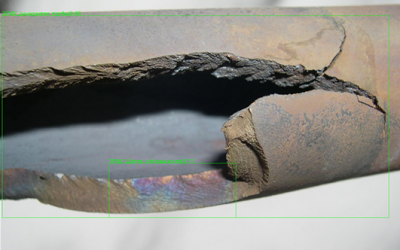

Hardware and software complex for pipes defects detecting

The business task of the project:

Reducing time and money expenditures for conducting thermal power station service maintenance. This process includes such activities as diagnostics of pipes for the presence of any breakage or defects with the help of drones (UAV). The received data is then analysed by means of programme software. Our objective was to implement a programme prototype for ensuring the possibility of detecting defects from photo and video data, received from UVA.

We broke our project for several stages for this purpose:

– developing software for data labeling in CVAT

– creating a data augmentation tool

– creating a synthetic data generation tool

– training neural network models (YoloV4, DetectoRS) to analyze images

– creating a client-serving application which would serve to download the video stream from the drone and to analyse the pipes’ condition

What we did and how we did it:

1. Research

Making an analytic report together with our MAI (Moscow Aviation Institute) partners was a significant part of our project. It was necessary for us to prove that the goal could be achieved by means of computer vision techniques and to choose the most efficient way of the project realization.

At the stage of compiling the report we did the following:

– we gathered information about SOTA solutions in the field of object detection within an image;

– we prepared and described 3 deep candidate architectures;

– we described the current state of datasets, data labeling tools and quality metrics in the similar tasks and projects;

– we described the options for using synthetic data generation tools.

2. Development

At the next stage of our project we realized our own system for training deep architectures, data labeling, logs and metrics collecting, and visualization based on the existing training systems. We created our own synthetic data generation tool, which sufficiently speeded up the process of gathering information for training neural networks.

Then we conducted training of the architectures that we chose on different datasets (the ones that were collected together with our partners and the ones that we generated ourselves). As a result, we devised a prototype of a web client-server application, in which we integrated neural networks trained to detect pipes defects. The client can download the data from the drone (in json format) to learn about both visual and technical state of the pipes.

The peculiarities of the project:

At the stage of the project realization, we managed to do a lot in a month period, including research and further development. The synthetic data generation tool that we created can be used for interrelated tasks for datasets generation and training neural networks.

Timeframe: 1 month

The client: UAV Center MAI

Year of the project implementation: 2020

The project team:

PM: Oleg Yusupov

R&D: Vadim Kondaratsev, Alexander Kruchkov, Roman Chumak

CG: Roman Chumak

DEV: Andrey Ivanov